3 reasons to not delay your migration to Dynamics 365 in the cloud

This article is contributed. See the original author and article here.

The “changing technology landscape” has become a common trope when discussing the cloud. I understand whyit helps contextualize the disruption and advancement we’re experiencing. But you know as well as I do, this “change” has happened. The on-premises solutions and infrastructure you built your business on, though once state-of-the-art, are now less adaptable, less useful, and less secure by the day.

Elasticity, scalability, and accessibility have never been more important, especially as new disruptions continue to test organizations, solutions, and processes alike. Moving to the cloud should be a business priority. Like any large project, it should not happen overnight. Build a plan, prepare your organization, and take manageable steps.

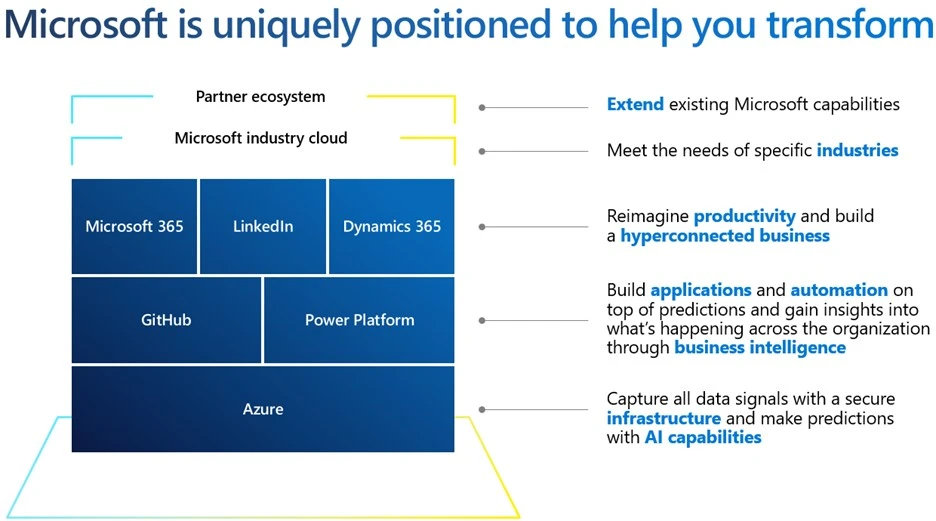

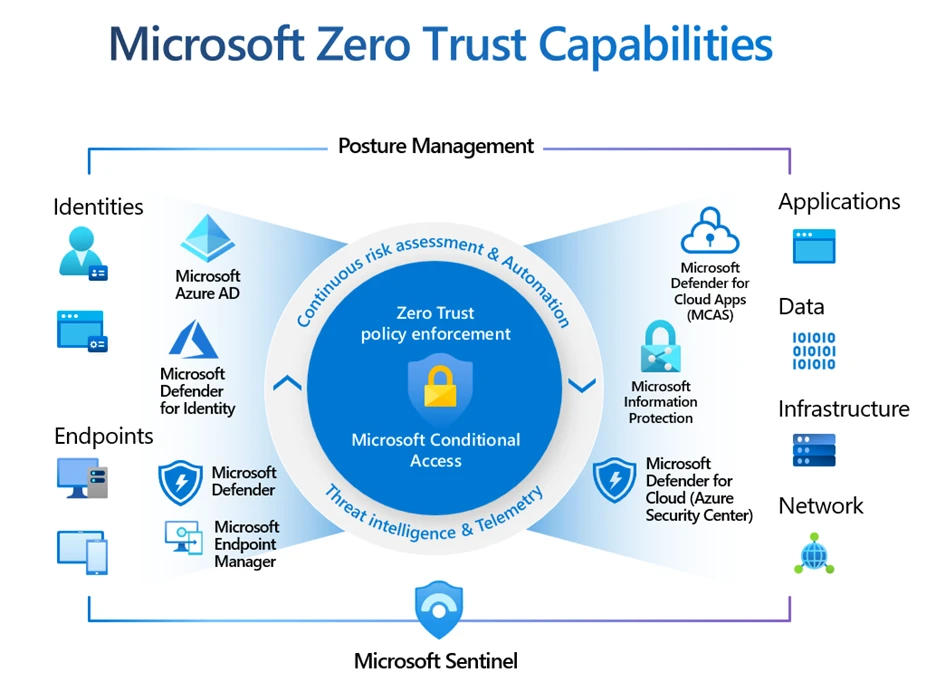

Start by understanding the Microsoft Dynamics 365 Power of the Cloud and the benefits it offers. Challenge the legacy thinking and misconceptions within your organization on whether your on-premises enterprise resource planning (ERP) or customer relationship management (CRM) can deliver on future needs and expectations. Don’t let nostalgia hold you back.

1. Good enough is no longer good enough

The first, and most common thing some business leaders say is, “What we have works just fine.” This can be especially true of customers in the finance and operations spaces, those utilizing Dynamics AX or other on-premises ERP solutions.

The idea of change or adopting something new can trigger this “good enough” reaction. The problem, of course, is that “good enough” masks complacencybecause it maintains the familiar. Within business, complacency is often the death of innovation and growth. Though some leaders still insist their on-premises solution is getting the job done, it’s becoming increasingly clear that the competition is using the cloud to accelerate growth.

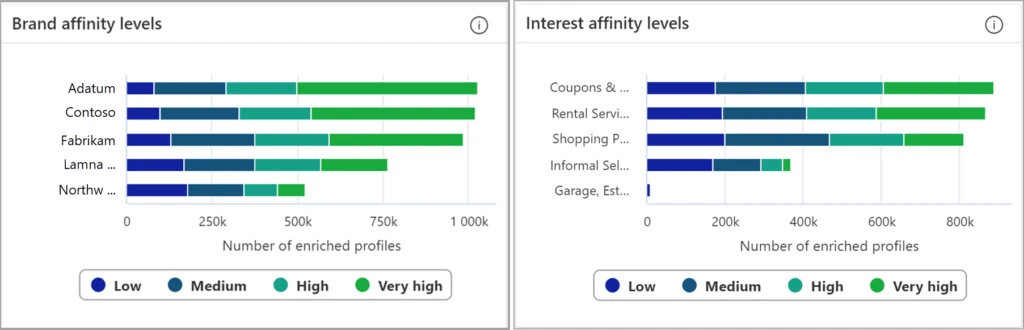

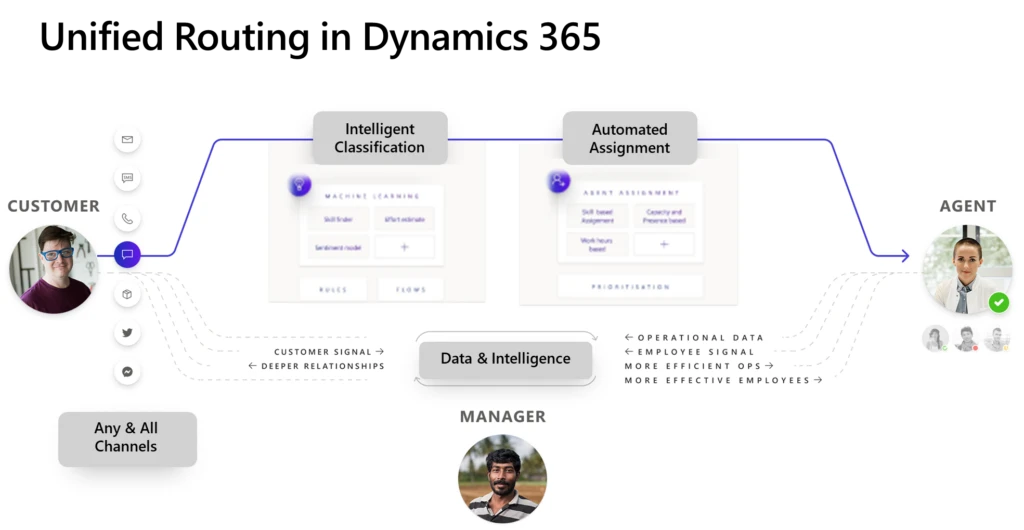

Dynamics 365 customers are taking advantage of data integrations, out-of-the-box functionality, plus advanced machine learning and predictive analytic capabilities to optimize legacy processes in real time, outpacing, outmaneuvering, and out-earning their on-premises peers.

2. Your needs are not as unique as you think

Another barrier to migration is the idea that your organizational needs are unique. This claim is common among on-premises organizations whose solutions have been heavily customized over the years, often addressing specific, point-in-time business needs.

Migration can enable an organization to eliminate cumbersome customization and their underlying expenses, infrastructure, and processes. Often what a customer views as a “unique” situation is less about the specialized needs of a given IT environment and more about what is perceived to be proprietary and a limited understanding of what is possible in the cloud.

Moreover, Microsoft works hard to advance our cloud solutions and ensure agility and adaptability to meet modern business requirements. Moving to the cloud is no small decisionthese are large technology projects that take planning and resources. While customizations do add complexity, these modifications should not preclude you from moving to the cloud. Out-of-the-box functionality; low-code, no-code; code-extensions; and ISV applications often eliminate the need for your legacy customizations.

Dynamics 365 offers flexibility and scalability designed to grow with customers’ businesses, allowing them to manage their organizations with unified data in real time.

3. Siloed doesn’t ensure security or compliance

Data preservation is a concern for most organizations. Vulnerabilities within your IT infrastructure and processes can leave systems susceptible to external threats and exploitation. Due to media mentions, many organizations believe the cloud is not safe.

The impenetrable solution is a myth, driven by the misconception that most attacks originate from outside an organization. No doubt traditional on-premises data solutions have been the stalwart cornerstone of many businesses’ IT operations. This firewall thinking served us well for a time. Not anymore. The threats have changed. On-premises solutions are reliant on existing policies, technology, and softwarewhich may or may not be up to datealong with their IT staff ensuring that the latest security processes and protocols are being maintained.

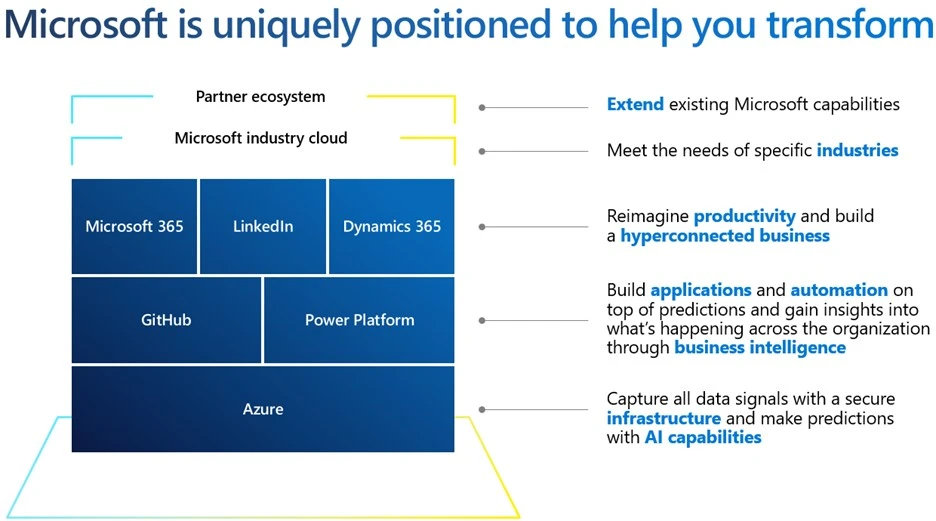

Within a modern cloud based solution, customers are able to take advantage of a Zero-Trust security framework. Zero Trust assumes potential threats have already “breached the gates.” Microsoft is proactive in verifying and reverifying credentials and authentications to minimize risks and threats.

Consider that cloud-based systems have millions of programs designed to check and update customers’ systems, creating backups and adjusting to current conditions, while on-premises solutions are reliant on IT staff to do those things individually. When measured against the increasing sophistication, speed, adaptability, and sheer criminal organization of cyber-attacks, it is nearly impossible for any company to protect itself in a siloed, non-cloud environment. Microsoft Cloud solutions regularly provide localized compliance, security, and governance updates. This translates into greater institutional and organizational efficiency and cost savings, allowing your teams and IT staff to focus on other projects and strategic priorities aligning to growth, leaving the security “burden” on Microsoft.

Your business resiliency may depend on when and how you adopt cloud functionality

Migrating to the cloud makes sense for efficiency and growth62 percent of companies that have migrated to the cloud reported an increase in customer satisfaction. Migrating to the cloud makes sense for customization and adaptabilitycompanies that have transitioned to cloud solutions reported a 44 percent increase in the speed of new product launches due to utility and specialized tools available to them. Migrating to the cloud makes sense for security and reliabilitycompanies that have transitioned to the cloud reported a 60 percent reduction in security incidents compared to their on-premises solutions.

Bear in mind that the benefits of the cloud can only fully be realized through successful migration, and Microsoft has developed the tools, resources, and expert support to help companies make the move in a quick, efficient, and cost-effective way.

Learn more

To learn more about how Microsoft Cloud solutions can help you modernize, customize, and keep you more secure, watch the Microsoft Dynamics 365 Power of the Cloud Webinar and join the migration community for resources and expert advice.

The post 3 reasons to not delay your migration to Dynamics 365 in the cloud appeared first on Microsoft Dynamics 365 Blog.

Brought to you by Dr. Ware, Microsoft Office 365 Silver Partner, Charleston SC.

Recent Comments